Spiral Classifier

EIMCO-K.C.P. Spiral Classifiers is art of separating the solid particles in a mixture of solids and liquid into fractions according to particle size or density by methods other than screening. In general, the products resulting are (1) a partially drained fraction containing the coarse material (called the underflow) and (2) a fine fraction along with the remaining portion of the liquid medium (called the overflow).

The classifying operation is carried out in a pool of fluid pulp confined in a tank arranged to allow the coarse solids to settle out, whereupon they are removed by gravity, mechanical means, or induced pressure. Solids which do not settle report as overflow.

EIMCO-K.C.P. Spiral Classifiers are mechanically the devices are powerfully built, and functionally they are versatile and flexible.

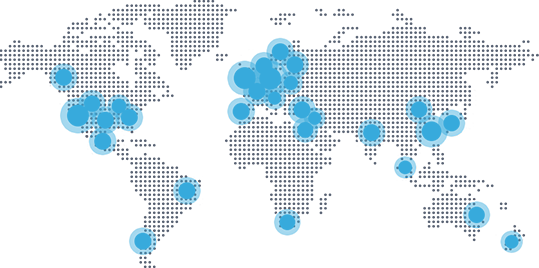

Today’s worldwide acceptance of EIMCO-K.C.P. Classifiers for washing and dewatering pulps, and in closed-circuit grinding is the result of many years of experience in solving wet classification problems. Because users’ needs vary so greatly, the Classifier is available in a wide range of spiral diameters and pitches, tank shapes and lengths allowing exact compliance with each user’s classification requirements.

Spiral diameters (0.3 m to 2.25 m):

Important in establishing a correct balance between overflow and raking capacity. Bears directly on accuracy of separation and control of agitation.

Spiral pitches (single / double / triple):

Number of ribbons is a factor in controlling degree of agitation. Each ribbon of advanced pitch gives greater raking capacity than equivalent ribbon of spiral using lesser pitch. Triple ribbon spiral highly advantageous for slow-speed operations requiring close separations and high raking capacities.

Adjustable spiral speeds:

Recommended speed of operation given in peripheral MPM is an individual consideration for each ore, and is governed by size, shape and gravity of particle, angle of repose of raking load and desired mesh of separation. Peripheral speeds between 6 and 60 meters per minute are available.

Pool depth:

Choice of pool depth is directly related to effectiveness of pool area. Series 90 units are employed for coarse separations on down to 212 micron (65 mesh); Series 125 units are employed for separations between 300 and 106 micron (48 and 150 mesh); Series 150 units are employed for separations of 150 micron (100 mesh) and finer.

Lifting device:

Lifting device eliminates necessity of draining tank during shutdowns. Classifier may be quickly put in operation after shutdown with tank fully sanded. Hydraulic-type standard on all units 1.2 m in diameter and larger. Fast action hand wheel-operated screw- type lift standard on 1.05 m and smaller.

Main Features

- Low Initial Cost.

- Low Operating and Maintenance Cost.

- Adjustable Flexible Lifting Device.

- Simple Flexible Lifting Device.

- Sectionalized Steel Flights.

- Replaceable Wearing Shoe